About Clearfield, Inc.

Clearfield, Inc. (NASDAQ: CLFD) designs, manufactures and distributes fiber optic management, protection and delivery products for communications networks. Our “fiber to anywhere” platform serves the unique requirements of leading incumbent local exchange carriers (traditional carriers), competitive local exchange carriers (alternative carriers), and MSO/cable TV companies, while also catering to the broadband needs of the utility/municipality, enterprise, data center and military markets. Headquartered in Minneapolis, MN, Clearfield deploys more than a million fiber ports each year. For more information, visit www.SeeClearfield.com or @ClearfieldFiber.

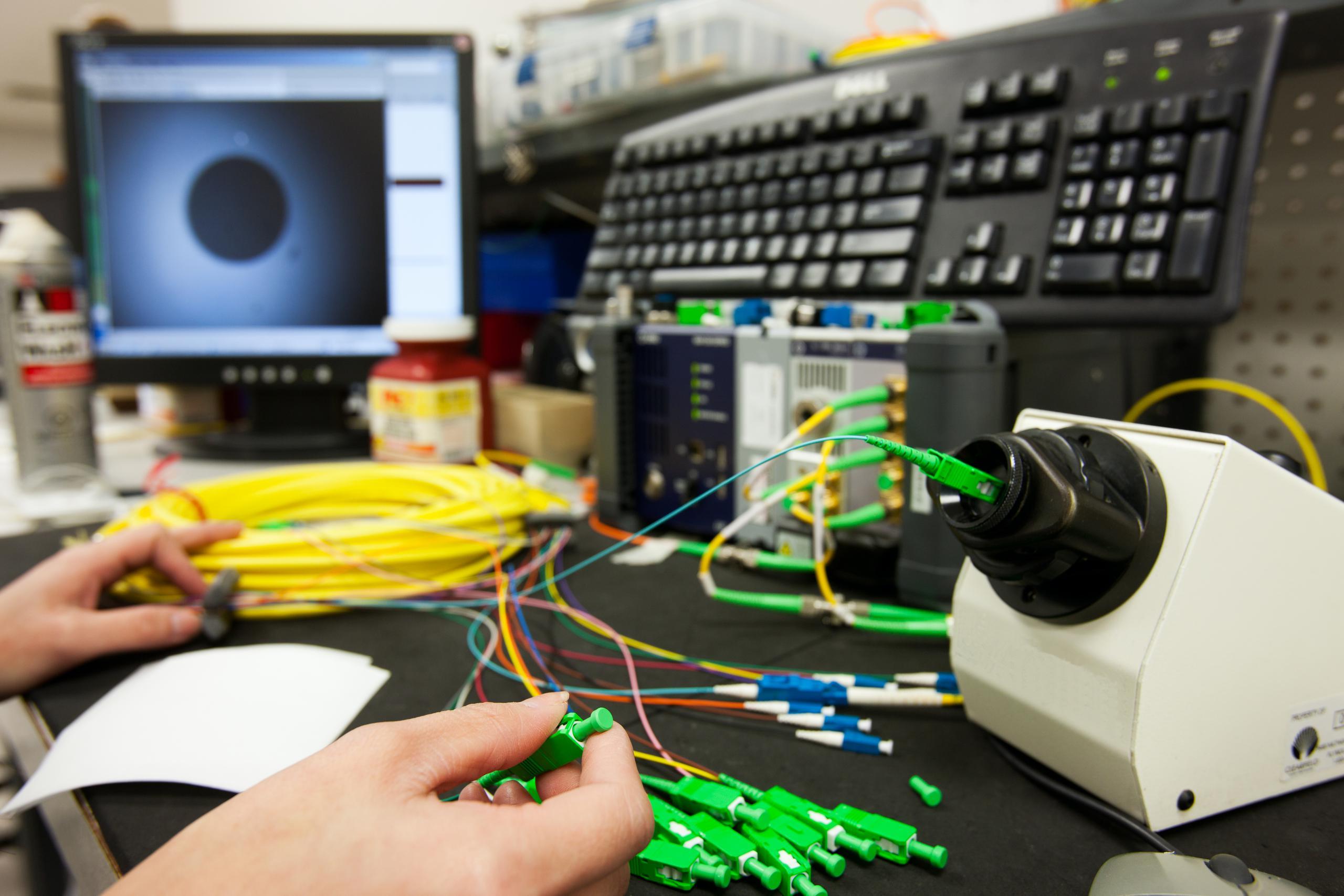

Clearfield fiber optic technologies enhanced communication at a remote mining operation, boosting productivity despite environmental factors

Background

A large-scale mining operation in South America faced persistent challenges caused by a lack of communication options. Due to the vast expanse of the open pit mine, employees required a reliable communication system capable of spanning considerable distances. Conventional cellular service was unavailable, creating the need for a purpose-built wireless infrastructure.

To enable this connectivity solution, the company contacted Clearfield to deploy reliable, rugged technologies to keep employees on the same page and boost productivity.

Challenge

Situated in a remote inland region, the mining site lacked access to traditional utility services. The operation had no access to municipal water or electricity, much less cell service or fiber broadband.

The tropical rainforest climate compounded the complexity of network deployment. Temperatures around 90 degrees Fahrenheit with high humidity cause electronic systems to wear out exponentially faster. The region’s two annual rainy seasons produce heavy precipitation and recurring flooding, conditions that can severely impact exposed infrastructure.

The environmental factors are in addition to the harsh conditions in a commercial mining operation. Heavy machinery, dust, and chemicals pose risks to equipment that’s not sufficiently ruggedized.

Solutions

To address these constraints, the mining company worked with Clearfield to design and implement a robust wireless networking solution. The proposed architecture required the strategic deployment of network switching hardware in an outdoor environment, directly subject to the region’s climatic extremes. And the several small cell stations would be powered entirely by solar energy.

Clearfield’s FieldSmart® FiberFlex™ 1700 cabinet offered the ideal solution to safeguard the powered equipment. Designed to meet NEMA standards and certified to Telcordia GR-487, this enclosure is engineered specifically to protect network electronics from extreme environmental factors, including moisture, heat, solar loading, and particulate intrusion. Stainless steel hardware and a GR-487-compliant powder coating ensure FiberFlex products hold up in the harshest industrial settings, including mining.

For fiber optic connectivity, the company deployed Clearfield’s FieldSmart Fiber Crossover Multi-Purpose (FxMP) Patch Panel. Also certified to Telcordia standards, this solution enabled technicians to perform direct splicing of outside plant fiber within the cabinet enclosure.

Results

The mining project highlights the necessity of ruggedized networking hardware in remote environments with intense rain and humidity. The ability to splice inside the Clearview Cassettes eliminated the need for separate splice cases. As a result, the FxMP patch panel design minimized hardware complexity, reduced points of failure, and streamlined maintenance.

Clearfield’s pour-in-place template for the FiberFlex 1700 cabinet sped up construction timelines while providing structural stability for the cabinet site. This accelerated deployment while maintaining compliance with industry best practices.

This resilient wireless communication infrastructure allowed workers to remain connected across vast distances despite the region’s extreme climate and infrastructural limitations. While working to increase communication, the company essentially struck “connectivity gold” – enabling greater productivity throughout the mining operation.