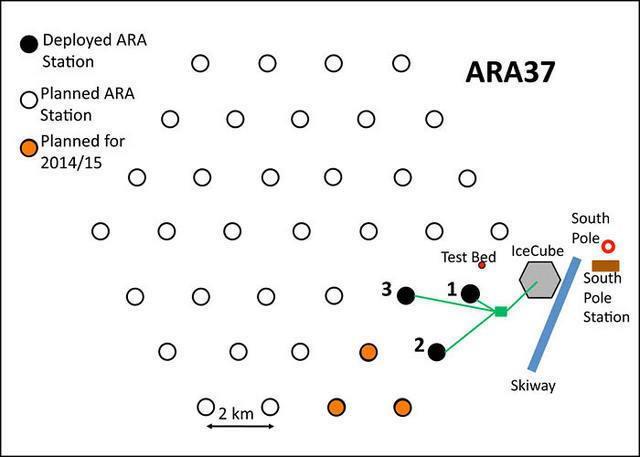

About Wisconsin IceCube Particle Astrophysics Center

For more information on the work being done, visit https://wipac.wisc.edu/science/projects/

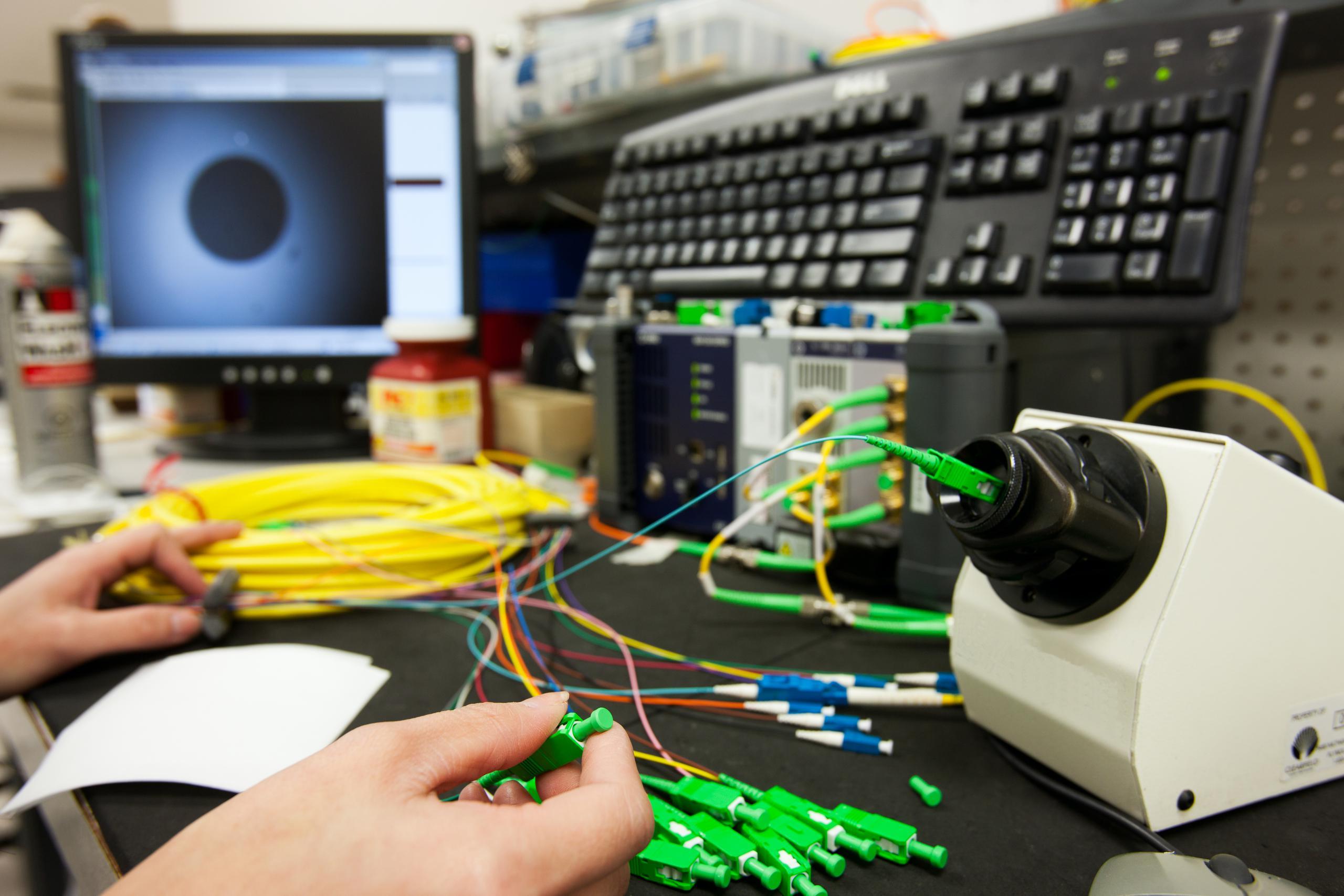

About Clearfield, Inc.

Clearfield, Inc. (NASDAQ: CLFD) designs, manufactures and distributes fiber optic management, protection and delivery products for communications networks. Our “fiber to anywhere” platform serves the unique requirements of leading incumbent local exchange carriers (traditional carriers), competitive local exchange carriers (alternative carriers), and MSO/cable TV companies, while also catering to the broadband needs of the utility/municipality, enterprise, data center and military markets. Headquartered in Minneapolis, MN, Clearfield deploys more than a million fiber ports each year. For more information, visit www.SeeClearfield.com.