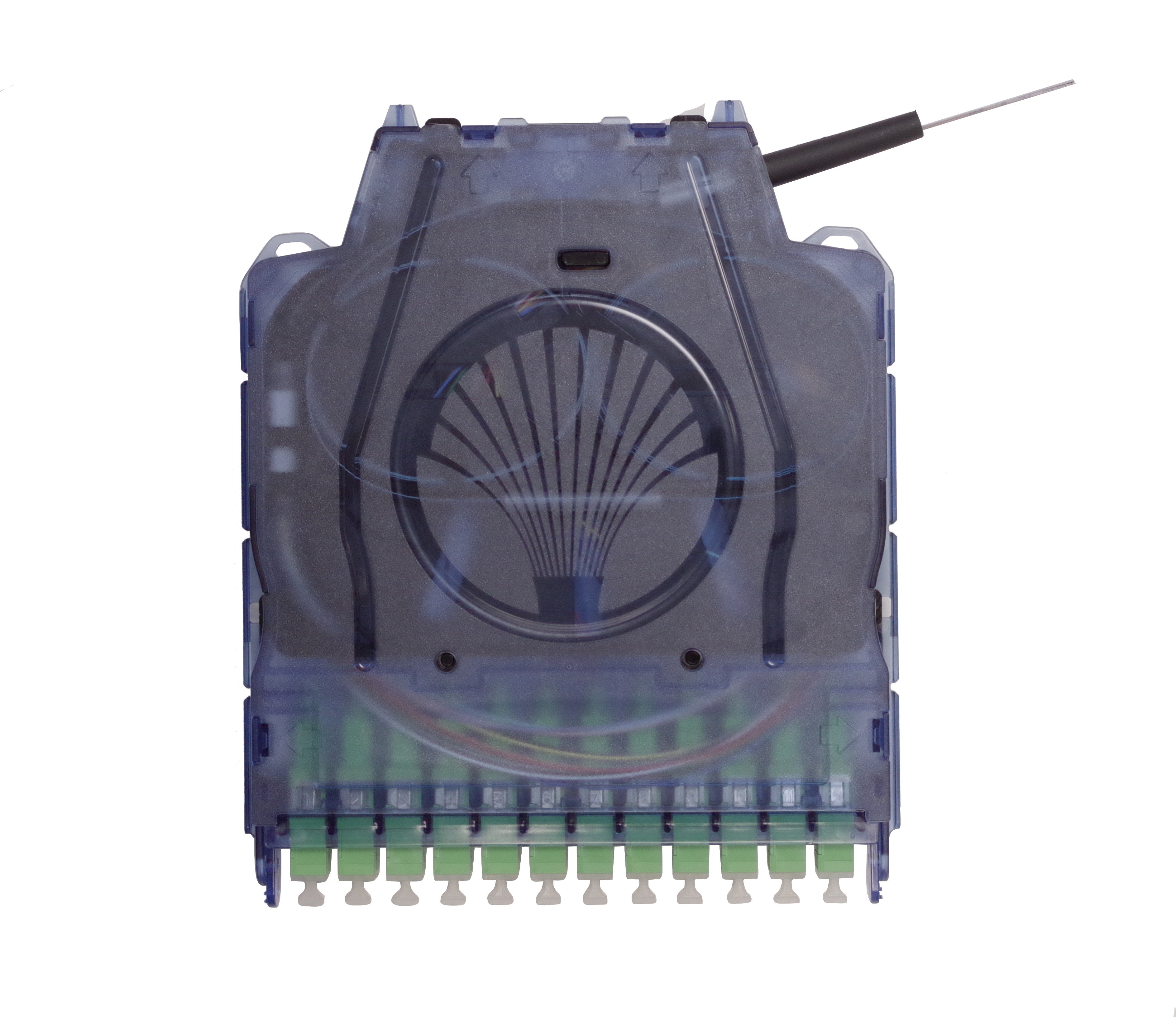

Clearfield’s Clearview® Patch and Splice Cassette provides for in-cassette splicing. Bringing the splice inside of the cassette means major savings in deployment lead times and your CAPEX budget. How?

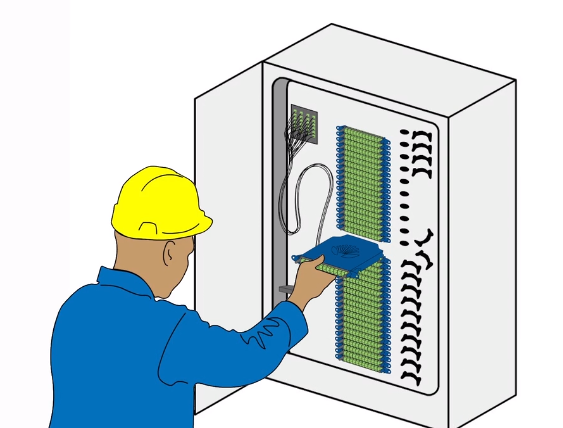

In a patch only network, a large percent of the time and cost of turn-up comes from the installation of a splice case and vault. The Clearview Blue Patch and Splice Cassette eliminates the need for a splice case by bringing the splice tray inside the cassette itself.

In-cassette splicing simplifies your installation, training and support. Incorporated into the Clearview Blue Cassette, this modular, scalable building block provides a unique, single architecture platform throughout the network, meaning savings are multiplied from the head end/central office all the way to the distribution point of your network.